Is nylon fiber (nylon-66) vegan?

Nylon fiber (nylon-66) is a vegan food ingredient.

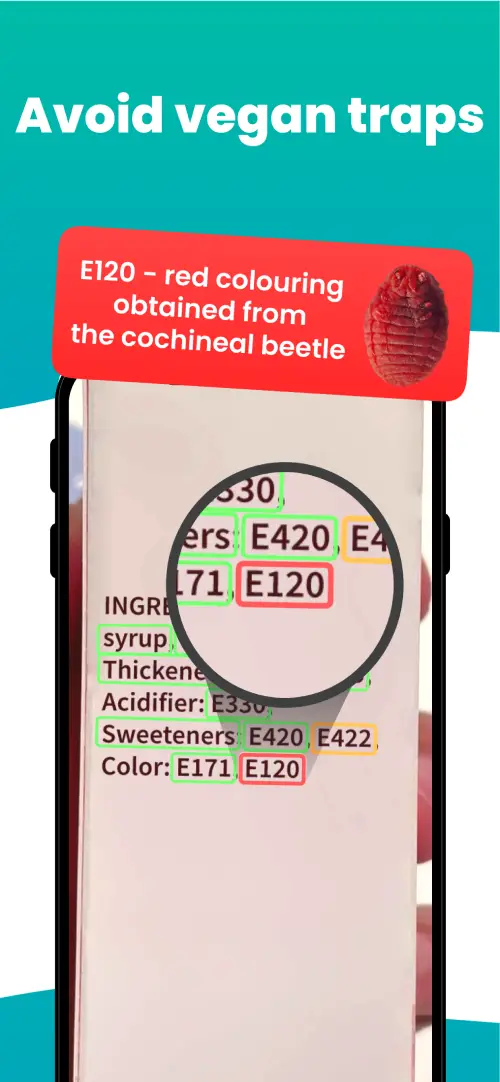

Checking out an ingredients list? 👇

"You are amazing, this has saved me so much time when grocery shopping!"

— Austin, a user who reached out with feedback

"It's been a great tool since starting my journey! You take a pic of the nutrition/ingredients, and it'll warn you of anything questionable or not vegan. 😁"

— Ashe, a Vegan For Beginners Facebook Group member

"Use a vegan app when you go shopping, I use WhatsVegan."

— Dóra, a Vegan For Beginners Facebook Group member

So, what is nylon fiber (nylon-66)?

Nylon fiber, also known as nylon-66, is a synthetic polymer that belongs to the polyamide family, a type of high-performance polymer commonly used in textiles and engineering applications. Its distinctive combination of strength, durability, and versatility make it an ideal material for a wide range of products. Derived from petroleum, nylon-66 has a number of unique properties that set it apart from other types of nylon. Its molecular structure consists of long chains of repeating units, giving it exceptional resilience and strength. This, combined with its ability to resist abrasion and wear, make it ideal for use in products that need to withstand harsh environmental conditions, such as automotive parts, electronic components, and industrial machinery. Nylon-66 is also resistant to heat, moisture, and chemicals, making it an excellent choice for textiles and fabrics. It can be easily extruded into fibers or filaments, which are then spun into yarns and woven into durable fabrics with a range of different textures and properties. One of the most popular uses of nylon-66 is in the production of nylon stockings and other hosiery. Nylon-66 fibers are tightly spun together to form a smooth, silky material that is both strong and flexible, with excellent elasticity and shape retention. This makes it ideal for clothing that needs to fit closely to the body, such as lingerie, swimsuits, and athletic wear. Nylon-66 is also widely used in the production of automotive components and electronic devices. Its high strength-to-weight ratio, coupled with its ability to withstand extreme temperatures and chemical exposure, make it an ideal material for use in parts such as fuel lines, air intake systems, and electrical insulation. In addition, nylon-66 has a number of other applications in various industries, including food packaging, medical devices, and sporting goods. Its toughness, resilience, and resistance to chemicals make it an ideal material for use in food packaging, while its ability to withstand sterilization and repeated use makes it a popular choice for medical devices such as catheters and surgical sutures. Overall, nylon-66 is a versatile and highly durable material that has a wide range of applications in various industries. Its unique combination of strength, resilience, and chemical resistance make it an ideal choice for products that need to withstand harsh environmental conditions or repeated use, and its ability to be easily fabricated into a variety of forms makes it an attractive option for manufacturers looking to develop new products with unique properties and characteristics. Nylon fiber (nylon-66) can also be blended with other fibers such as wool, cotton, or polyester to produce fabrics that combine the unique properties of both materials. For instance, a blend of nylon-66 and wool produces a warm, lightweight fabric that is ideal for outdoor apparel. Similarly, a combination of nylon-66 and cotton produces a breathable fabric that is suitable for clothing worn in warm weather. Nylon-66 is also used in the production of various household items, such as carpets, rugs, and upholstery. Its exceptional durability and stain resistance make it a popular choice for these products, as they need to withstand heavy use and frequent cleaning. Nylon-66 provides excellent colorfastness, which means that it retains its color even after prolonged exposure to sunlight and repeated washing. Moreover, nylon-66 is commonly used in the manufacture of ropes and cords for a variety of applications, including rock climbing, camping, and sailing. Its high tensile strength, combined with its abrasion resistance and ability to stretch without breaking, make it a reliable and safe material for these purposes. Nylon-66 also finds application in 3D printing. Nylon-66 filaments can be 3D-printed into parts and components with high tensile strength, durability, and resistance to wear and tear. 3D-printed nylon-66 parts are used in various industries, ranging from aerospace and automotive to medical and consumer products. In medicine, nylon-66 can be used as a matrix for drug delivery and tissue engineering. Its biocompatibility and biodegradability make it a potential candidate for controlled drug release, implant coatings, and drug-eluting stents. Nylon-66 can also be electrospun into nanofibers, which can be used as scaffolds for tissue engineering. These nanofibers mimic the natural extracellular matrix of tissues and guide the regeneration of damaged tissues. Furthermore, nylon-66 can be recycled and used in the manufacture of various products. The recycling process involves breaking down the nylon-66 into its constituent monomers, which can then be used to produce new nylon fibers and other products. The recycling of nylon-66 provides environmental benefits by reducing waste and decreasing the reliance on petroleum-based raw materials. In conclusion, nylon-66 is a versatile and durable synthetic polymer that finds application in various industries, ranging from textiles and fabrics to automotive and medical. Its combination of strength, resilience, and chemical resistance make it a popular choice for products that require high performance and durability. Additionally, its blendability, recyclability, and biocompatibility make it an attractive material for research and development in emerging fields such as sustainable materials, tissue engineering, and drug delivery. Nylon-66 is also an essential material in the production of airbags, which are vital components of automotive safety systems. Nylon-66 fibers are used to create the woven material that forms the airbag, and their high tensile strength and durability are crucial in ensuring the proper deployment and protection that airbags provide in case of an accident. Moreover, nylon-66's excellent barrier properties make it an ideal choice for food packaging. It is used in the production of films and other types of packaging that help to preserve the freshness and quality of food for longer periods of time. Nylon-66 provides outstanding oxygen and moisture barrier properties, which help to keep food fresh and extend its shelf life. Nylon-66's toughness and durability also make it a suitable material for the construction of lightweight and high-strength structures, such as bridges, buildings, and aircraft. Its low weight-to-strength ratio makes it an excellent choice for reducing the weight of structures without sacrificing strength and performance. In the fashion industry, nylon-66 has found favor as a versatile and resilient material that can be used in a variety of clothing items and accessories. High-end fashion houses such as Prada and Gucci have incorporated nylon-66 into their collections, using it to create everything from handbags and backpacks to suits and dresses. Nylon-66 is also an essential component of fishing lines, particularly those used for deep-sea fishing. Its shock resistance and abrasion resistance make it an ideal material for withstanding the demands of this rigorous activity. In the music industry, nylon-66 is used to manufacture strings for acoustic and classical guitars. Its durability and resistance to stretching and breaking make it an ideal choice for strings that are designed to produce clear, bright tones and last a long time. Additionally, nylon-66 can be used for 3D printing musical instruments, such as guitars and violins. Its high tensile strength and flexibility allow for the creation of complex and intricate designs that are difficult to achieve with other materials. In the field of sports, nylon-66 is used in the production of high-performance athletic gear, such as running shoes, sports bras, and compression garments. Its moisture-wicking and quick-drying properties help to keep athletes comfortable and dry during even the most intense workouts. Finally, nylon-66's electrical insulation properties make it an outstanding choice for use in the production of cables and wires. Its ability to withstand high temperatures and maintain its mechanical properties make it a versatile and reliable material for these applications. In conclusion, nylon-66's numerous properties and characteristics make it a versatile material that finds application in various fields and industries. Whether it is used for durable textiles, high-performance automotive parts, robust structures, reliable food packaging, or advanced medical devices, nylon-66 provides unique benefits that set it apart from other materials. Its blendability, recyclability, and biocompatibility make it a promising material that may have even more applications in the future.

How to quickly find the source of ingredients like nylon fiber (nylon-66)?

We've built a database of 49359 ingredients (and growing), classified as "vegan", "non-vegan", or "maybe vegan".

We use it in our vegan ingredients scanner, which is the best way to avoid non-vegan ingredients - you take a picture of a product's ingredient list, and the app tells you if the product is vegan or not.

Check out other ingredients:

Is nylon fiber vegan?Is triethanolamine (tea) vegan?Is nylon-66 vegan?Is ci77288 vegan?Is ci778161 vegan?Is ci 778161 vegan?Is peg-40 vegan?Is matricaria chamomilla flower water vegan?Is spearmint oil vegan?Is vitis vinifera seed oil vegan?Is rabbiteye blueberry vegan?Is limeblad vegan?

We'll never send you spam.