Is carboxy methyl cellulose e466 vegan?

Carboxy methyl cellulose e466 is a vegan food ingredient.

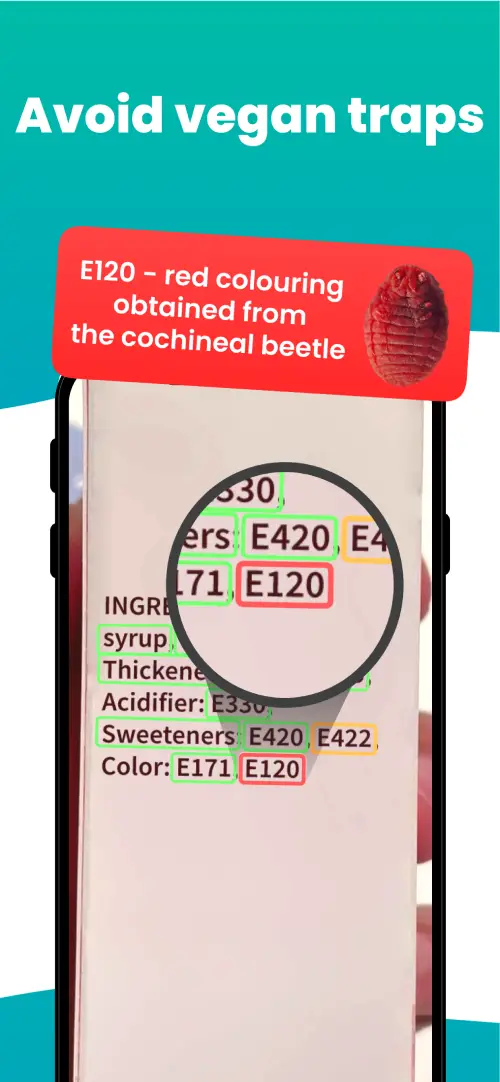

Checking out an ingredients list? 👇

"You are amazing, this has saved me so much time when grocery shopping!"

— Austin, a user who reached out with feedback

"It's been a great tool since starting my journey! You take a pic of the nutrition/ingredients, and it'll warn you of anything questionable or not vegan. 😁"

— Ashe, a Vegan For Beginners Facebook Group member

"Use a vegan app when you go shopping, I use WhatsVegan."

— Dóra, a Vegan For Beginners Facebook Group member

So, what is carboxy methyl cellulose e466?

Carboxy methyl cellulose (CMC) is a water-soluble anionic polymer derived from cellulose. It is used as a thickener, emulsifier, and stabilizer in a variety of food and non-food applications. This ingredient is commonly referred to as CMC or cellulose gum. In food applications, CMC is used as a thickener and stabilizer in a wide range of products including dairy products, baked goods, dressings and sauces, beverages, and confectionery products. In dairy products, CMC is used to improve the texture and mouthfeel of products like ice cream, yogurt, and cheese. CMC is also used in baked goods to improve dough handling and to provide moisture retention, which can help prevent staling. In dressings and sauces, CMC functions as a thickening agent and can improve stability and reduce syneresis. In beverages, CMC can be used as a stabilizer to suspend particles and to improve mouthfeel. In addition to its food applications, CMC is used in a wide range of non-food applications. It is used as a binder in pharmaceutical tablets and capsules, and as a thickener and stabilizer in personal care products like toothpaste and shampoo. CMC is also used as a drilling fluid additive in the oil and gas industry. One of the key benefits of CMC is its water-solubility, which makes it easy to incorporate into a wide range of products. It is also stable over a wide range of pH levels and temperatures, which makes it versatile and easy to use. CMC is typically produced from wood pulp or cotton cellulose, which is chemically modified to produce the anionic polymer. The degree of substitution (DS) is an important parameter that influences the properties of the CMC. This refers to the number of carboxymethyl groups that are attached to each anhydroglucose unit in the cellulose chain. CMC with higher DS values tends to have greater solubility and viscosity. One of the key considerations when using CMC is the concentration and usage level. The appropriate concentration and usage level will depend on the specific application and the desired functional properties. It is important to ensure that the CMC is thoroughly dispersed to avoid clumping and to ensure that it is evenly distributed throughout the product. In summary, carboxy methyl cellulose is a versatile ingredient that provides thickening, stabilizing, and emulsifying properties in a wide range of food and non-food applications. Its water-solubility, stability, and versatility make it a popular choice for many different industries. When using CMC, it is important to consider the appropriate concentration and usage level to achieve the desired functional properties. There are many advantages to using carboxy methyl cellulose over other thickeners or stabilizers. One of the most noteworthy benefits is that CMC can be used in small quantities for significant results. Additionally, CMC does not mask the natural flavor of food products, which is a significant advantage in the food industry. CMC is also widely used in the production of gluten-free foods. In the absence of gluten, food ingredients tend to fall apart and become crumbly. Gluten free recipe developers find relief in CMC as it responds to stress and stabilizes dough, increasing water absorption in the mixture, holding ingredients together, and improving the final texture of baked goods . In pharmaceuticals, carboxy methyl cellulose is used as an inactive ingredient in tablets, capsules, and syrups. CMC helps to disintegrate the tablet or capsule in the stomach and release the active ingredient for absorption in the body. It is commonly used in over-the-counter pain medications, antacids, and cough syrups. In personal care products, CMC is used as a thickener and emulsifier, especially in lotions, creams , and shampoo. CMC-based lotions and creams have a non-greasy texture and provide a more luxurious feel on the skin than similar products that use other synthetic thickeners. It is a common ingredient in baby wipes due to its absorbent properties and low irritancy to the skin. CMC lends itself into industrial processes as well. It has sturdy and elastic qualities that make it a preferred choice for printing inks, paints, and adhesives because of its consistency and excellent coverage properties. It also has an inherent ability to disperse and mix powder in water-based solutions. Aside from its many industrial and commercial Usages, carboxy methyl cellulose has also found application in agriculture as a hydrogel. The term hydrogel refers to a material that can absorb and hold water in its structure. Farmers mix the hydrogel with fertilizer mixtures, creating a water-saving system that enables more plants to grow by increasing the water retention capacity of the soil. In summary, CMC is a versatile ingredient utilized extensively in industries that rely on gels, adhesives, paints, and gums since it holds water by forming a three-dimensional matrix that makes it appropriate for industrial applications. Its wide variety of applications covers almost every industry, including the food, pharmaceutical, and personal care industries. CMC is predominantly used due to its numerous benefits - high solubility, stability, non-toxicity and combability with other ingredients, good suspension, and emulsifying properties - that can enhance the different characteristics of a product. Carboxy methyl cellulose (CMC) is highly prevalent in the food industry as an essential ingredient in a variety of products such as salad dressing, sauces, and soups. It is commonly used to thicken such products by trapping water molecules, creating a gel-like consistency that has a smooth texture. In powdered soups or sauces, a small concentration of CMC powder is added after it is cooked to maintain the desired viscosity of the product. It prevents the separation of ingredients and maintains the perfect consistency throughout the life of the product. CMC is also used as a food preservative due to its emulsification capacity that prevents the separation of the mixture’s components. It helps to maintain the quality and smooth texture of food products for a more extended period. Using CMC film-forming capabilities for food packaging increases shelf life and prevents the food from spoiling by creating a barrier between the food and the environment. Apart from food preservatives and stabilizers, CMC is well known for its use in the paper industry. Due to its water retention properties, CMC acts as a binder, holding paper fibers together during the paper-making process, preventing paper from tearing after pressing, and improving paper's workability. CMC helps to improve the printing performance of paper, reduces wear on printing equipment, and enhances ink retention on paper. Carboxy methyl cellulose is also widely used in the construction industry. As a flocculent, CMC is utilized in the manufacture of ceramic tiles. The ingredient acts as a binding agent for the granules that make up the tiles. This increases the integrity of the tiles when they bond together and helps them retain their shapes during firing. CMC is also used in the construction of drilling fluids to provide stability and water retention properties to the fluid. Drilling fluids are used in oil and gas drilling operations to lubricate the drill bit and carry out rock fragments, dirt, and fluids to the surface. As a result, CMC is an essential additive that prevents the loss of drilling fluids to permeable soils. In textile production, carboxy methyl cellulose is used to provide stability, and an even dispersion of all fibers in a mixture. It also acts as an anti-bleeding agent, preventing colors from running during washing. CMC paste is used in the printing of textiles for its thickening qualities and the ability to hold the pigment in place and prevent bleeding. In conclusion, carboxy methyl cellulose is an essential ingredient that serves various purposes in the manufacturing industry, from pharmaceuticals to paper, textiles, and construction. Its versatility arises from its capacity to retain water and provide stability to a variety of substances, from food to drilling fluids, where the suspension of particles is essential. The unique properties of CMC enable manufacturers to create higher quality and more durable products suitable for their respective markets.

How to quickly find the source of ingredients like carboxy methyl cellulose e466?

We've built a database of 49359 ingredients (and growing), classified as "vegan", "non-vegan", or "maybe vegan".

We use it in our vegan ingredients scanner, which is the best way to avoid non-vegan ingredients - you take a picture of a product's ingredient list, and the app tells you if the product is vegan or not.

Check out other ingredients:

Is guar gum e412 vegan?Is caramel as color vegan?Is vitamin b9 vegan?Is fd& c blue 1 vegan?Are distilled vinegars vegan?Is ammonium aluminum sulphate vegan?Is fd &c blue 1 vegan?Is fd& c red 40 vegan?Is jus de mandarine concentré vegan?Is lotus root vegan?Is sel de table vegan?Is extrait de graine de guarana vegan?

We'll never send you spam.